TM 10-3990-205-12&P

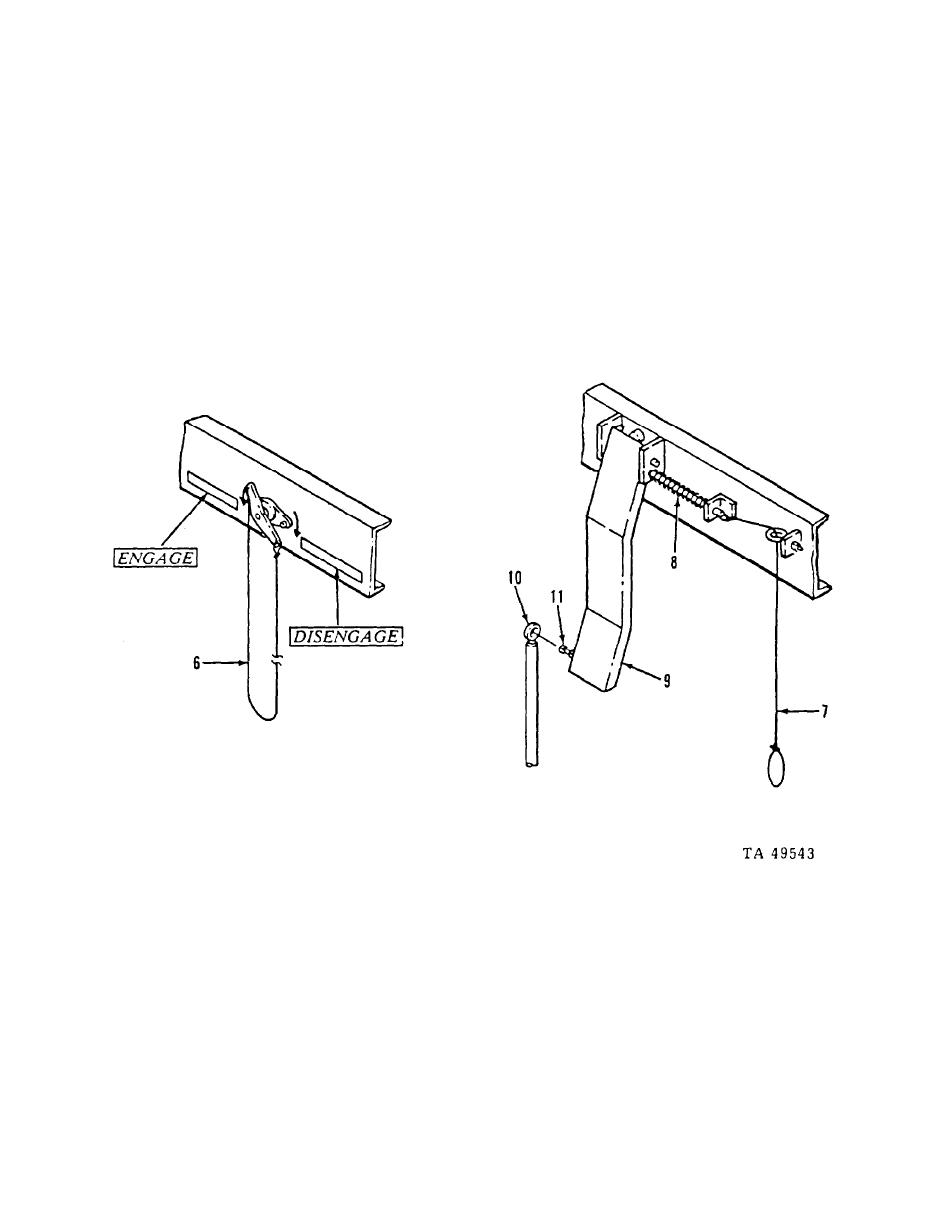

h. Pull the control cable (7) to disengage the spring pin (8) from the alignment arm

(9). Place the eyebolt (10) on the end of the alignment arm positioning rod on the

capscrew (11). and move the alignment arm (9) to the up position. Release the control

cable (7) and check to see that the spring pin (8) returns to the engaged position,

and that the alignment arm (9) is pinned securely in the up position. Return the align-

ment arm (9) to the down position.

i.

.

Repeat the above procedure until all six of the alignment arms (9) have been checked.

2-4 OPERATING PROCEDURE

The spreader has six alignment arms, but only two arms on one side and one on the end

of the spreader are sufficient to align the spreader on a freight container. The choice

of which arms to use depends on the relative location of the hoisting equipment and the

container. When the spreader has been properly lubricated, the twist locks in the disengaged

position, and the selected alignment arms are pinned in the down position, the spreader

is in configuration for coupling to a freight container.

2-8