TM 5-3895-367-14&P

Section III. OPERATION UNDER USUAL CONDITIONS

2-6. SPREADING AGGREGATE.

a.

Have unit maintenance do the following:

(1)

Remove taillights (para 4-11).

(2)

Remove transport truck and tongue (para

4-12).

(3)

Install truck hitch on dump truck (para 4-

13).

(4)

Install operator’s platform on spreader

(para 4-14).

(5)

Couple spreader to dump truck (para 4-

15).

WARNING

Do not attempt to install inserts while

feed roll or agitator are turning. Any

contact with moving agitator or feed

roll could cause severe Injury.

b.

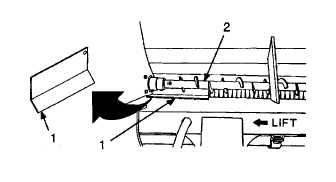

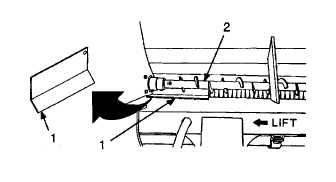

If necessary, remove inserts (1) from spreader

toolbox and install under agitator (2) to reduce width of

spread.

c.

Ensure that truck tailgate clears the spreader so

that flow of aggregate will be smooth.

WARNING

Spreader

operator

must

wear

protective

face

mask

and

respirator

to

avoid

breathing

stone dust. Failure to follow this

warning could result in injury .

Check with local medical and

safety office to ensure proper

equipment and fit.

Spreader

operator

must

wear

respirator during hot bituminous

tar chipping road resurfacing.

Failure to follow this warning

could result in injury

or death. Check with local medical and safety office to

ensure proper equipment and fit.

Loose clothing can be caught in agitator and feed

roll. Spreader operator must not wear loose clothing,

open shirts, Y length jacket or coat, or hanging scarf

while operating spreader. Failure to follow this

warning could result in severe injury or death.

Flying debris. Spreader operator must wear eye

protection. Failure to follow this warning could result

in eye injury or loss of vision. Check with local

medical

and

safety

office

to

ensure

proper

equipment and fit.

Spreader operator must wear hearing protection.

Failure to follow this warning could result in hearing

loss or degradation. Check with local medical and

safety office to ensure proper equipment and fit.

Spreader operator must wear steel toed shoes.

Failure to follow this warning could result in injury.

Check with local medical and safety office to ensure

proper equipment and fit.

d.

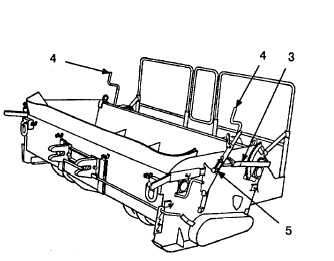

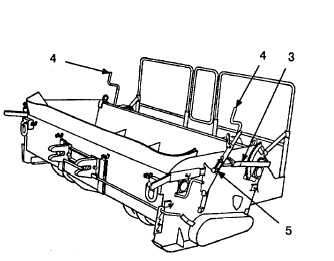

Set gate adjusting lever (3) for desired flow of

aggregate.

e.

Use gate adjusting screws (4) to make fine

adjustments to aggregate flow. Gate adjusting screws

can be set separately for a tapered spread.

f.

To operate spreader in a forward direction, set

feed roll control lever (5) to FORWARD SPREAD. To

operate spreader In a backward direction, set feed roll

control lever to REVERSE SPREAD. To change setting

of feed roll control lever, dump truck and spreader must

be completely stopped.

2-7