TM 5-3895-367-14&P

4-41. TRACTION WHEEL ASSEMBLY REPAIR.

This task covers:

a.

Removal

d.

Assembly

b.

Disassembly

e.

Installation

c.

Cleaning and Inspection

INITIAL SETUP

Tools:

Equipment Conditions:

Tool Kit, General Mechanic’s Automotive

References

Lifting device with 2000 lb capacity

Para 4-15

Spreader uncoupled from dump truck.

Lifting slings or chains

Para 2-1

Agitator clutch disengaged.

Blocking material

Para 2-1

Feed roll control lever set to NEUTRAL.

Torque wrench

Para 4-14

Operator’s platform removed from

Materials/Parts:

spreader.

Dry cleaning solvent item 10, Appendix E)

Para4-12

Transport truck and tongue removed

GAA (Item 3, Appendix E)

Para 4-27

Toolbox removed.

Para 4-27

Toolbox removed.

Twenty lockwashers

References:

Personnel Required:

Three

TM 9-214

TM 9-2610-200-14

a. Removal.

NOTE

The following procedure can be used

for either set of traction drive wheels.

Differences between the two sides are

noted in the procedure.

(1)

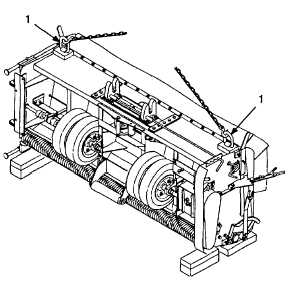

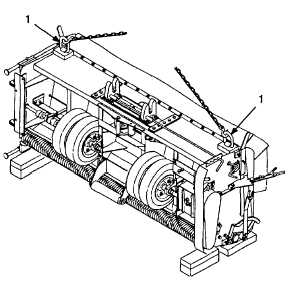

Connect lifting slings or chains to D-rings (1)

at front of hopper.

WARNING

Do not allow heavy components to

swing while suspended by a lifting

device. Exercise extreme caution when

working near a cable under tension.

Failure to follow this warning may

result in severe injury to personnel.

NOTE

Two people should balance spreader

while the third person operates lifting

device.

(2)

Using a suitable lifting device, slowly lift

spreader (2000 lb) until it is suspended from

D-rings (1) at front of hopper.

(3)

Place blocking under spreader. Slowly lower

spreader onto blocking. Ensure that

spreader is secure and stable before

removing lifting device.

4-66