TM 5-3895-367-14&P

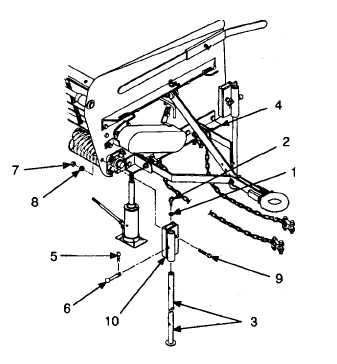

4-25. LEVELING LEG REPAIR.

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools:

Equipment Conditions:

Tool Kit, General Mechanic’s Automotive

References

12-ton hydraulic jack

Para 4-12

Transport truck installed on spreader.

Materials/Parts:

One lockwasher

a.

Removal.

NOTE

This procedure can be used for either

leveling leg.

(1)

Loosen nut (1) and remove eyebolt (2)

from top of leveling leg (3). Remove nut

from eyebolt.

(2)

Place hydraulic jack under bottom angle

(4). Jack up spreader enough to take

weight off leveling leg (3)

(3)

Remove lock pin (5) and pin (6) from

leveling leg (3). Jack up spreader enough

to remove leveling leg.

(4)

Remove nut (7), lockwasher (8), screw (9),

and bracket (10) from spreader. Discard

lockwasher.

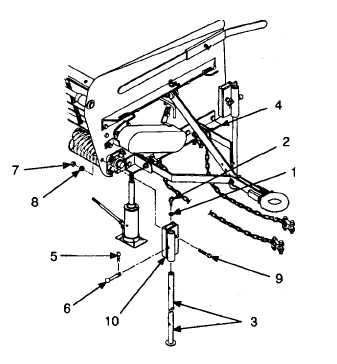

b.

Installation.

(1)

Install bracket (10) on spreader using

screw (9), new lockwasher (8), and nut

(7).

WARNING

Install leveling leg in lowered position. If

leveling leg is not lowered, spreader will

fall over when hydraulic jack is removed.

Failure to follow this warning could result

In severe injury or equipment dam- age.

(2)

Slide leveling leg (3) into bracket (10).

Secure leveling leg in lowered position

with pin (6) and lock pin (5).

(3)

Screw nut (1) onto eyebolt (2).

(4)

Screw eyebolt (2) into top of leveling leg

(3). Tighten nut (1) against leveling leg.

(5)

Lower and remove hydraulic jack.

4-44